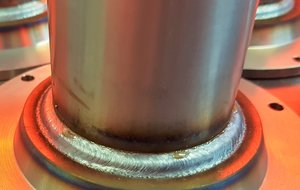

TIG (Tungsten Inert Gas)

The process of arc welding with infusible electrode with the protection of inert gas (TIG or GTAW) is an autogenous welding process for fusion in which the heat source is an electric arc produced between an electrode and the workpiece.

+ Advantages

- Arc stability

- Visibility of welding bath because there is no filler material

- Highly concentrated heat source (minimum heat input) compared to oxyacetylene welding

- Good for thin materials

- Excellent cleaning of the joint

- Can be automated

- Disadvantages

- Low productivity

- Need for accurate couplings

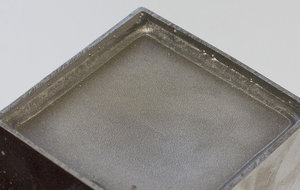

MIG - MAG

MIG (Metal-arc Inert Gas) / MAG (Metal-arc Active Gas)

The arc welding process with wire under inert gas protection is an autogenous welding process for fusion in which the heat source is an electric arc produced between a fuse wire and the workpiece.

The only difference between MIG and MAG is the gas used to protect the welding bath.

+ Advantages::

- Flexible and versatile process

- Easily automated

- Provides a high deposition rate (5 ÷ 20 Kg/h)

- Welding almost all ferrous and non-ferrous materials

- High welding quality

- No production of welding swarf

- High productivity

- Disadvantages:

- Presence of welding spatter

- Cannot be used on thin substances

Robotic MIG - MAG

The robotic MIG/MAG welding procedure can be completely automated:

+ Main advantages

- Robotic welding system

- Automatic machines in production lines

- Dedicated equipment for high productivity

Many applications of robotics and automation in welding have been developed and are actively used throughout the world.

In the latest statistics, 30% of robots in the world are used in welding—27% in Europe and 19% in Italy.